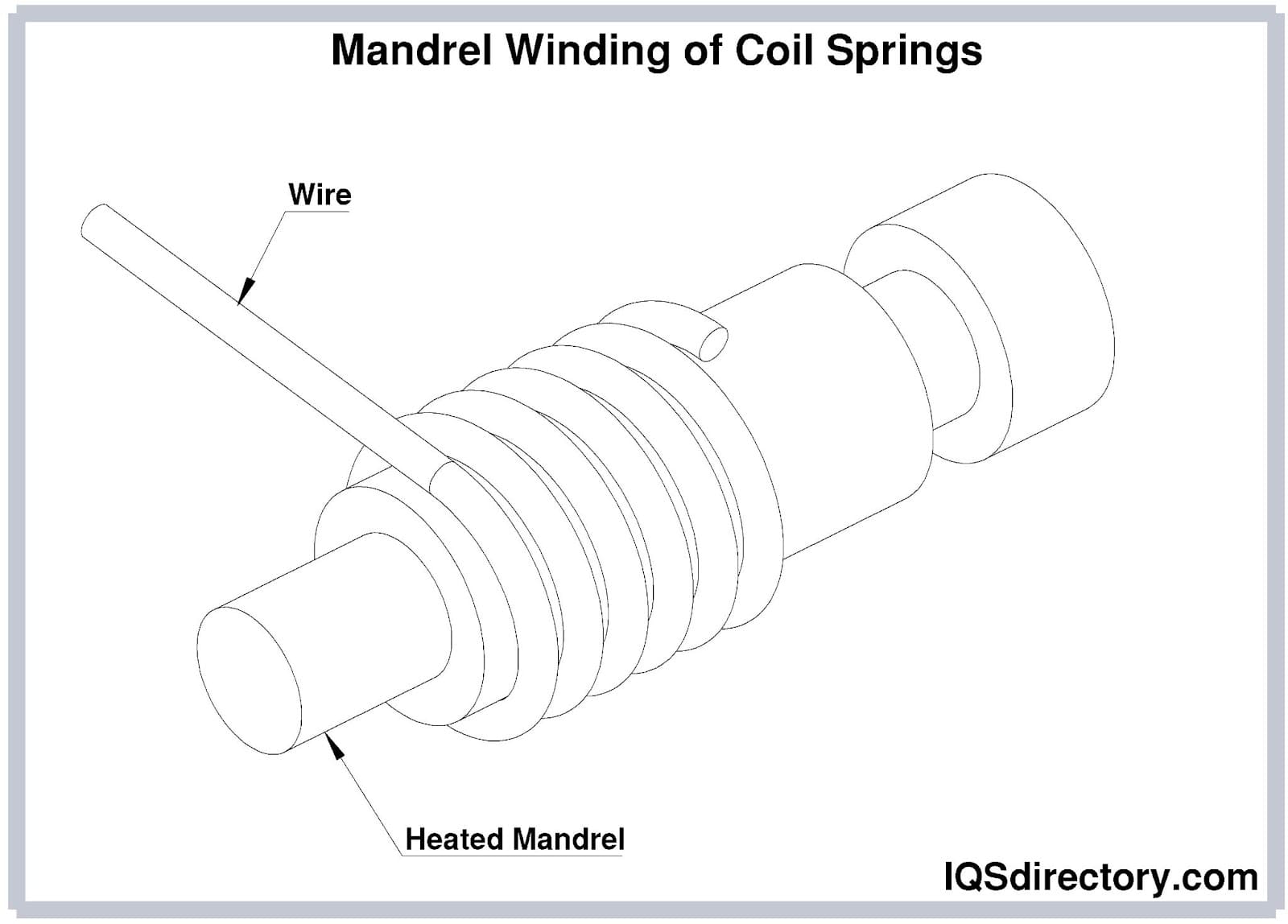

Mandrel structure and mandrel-winding process principle.

Download scientific diagram | Mandrel structure and mandrel-winding process principle. from publication: Heat transfer simulation and analysis of mandrel for heated-mandrel winding method of tapered shell | With the advantages of high production efficiency and good product quality, the heated-mandrel winding method has been widely used for high-pressure shells. Previous research results show that it is very important to ensure that the axial temperature is distributed as | Shell, Wind and Heat Transfer | ResearchGate, the professional network for scientists.

Comparison of filament winding methods: a Filament winding on mandrel

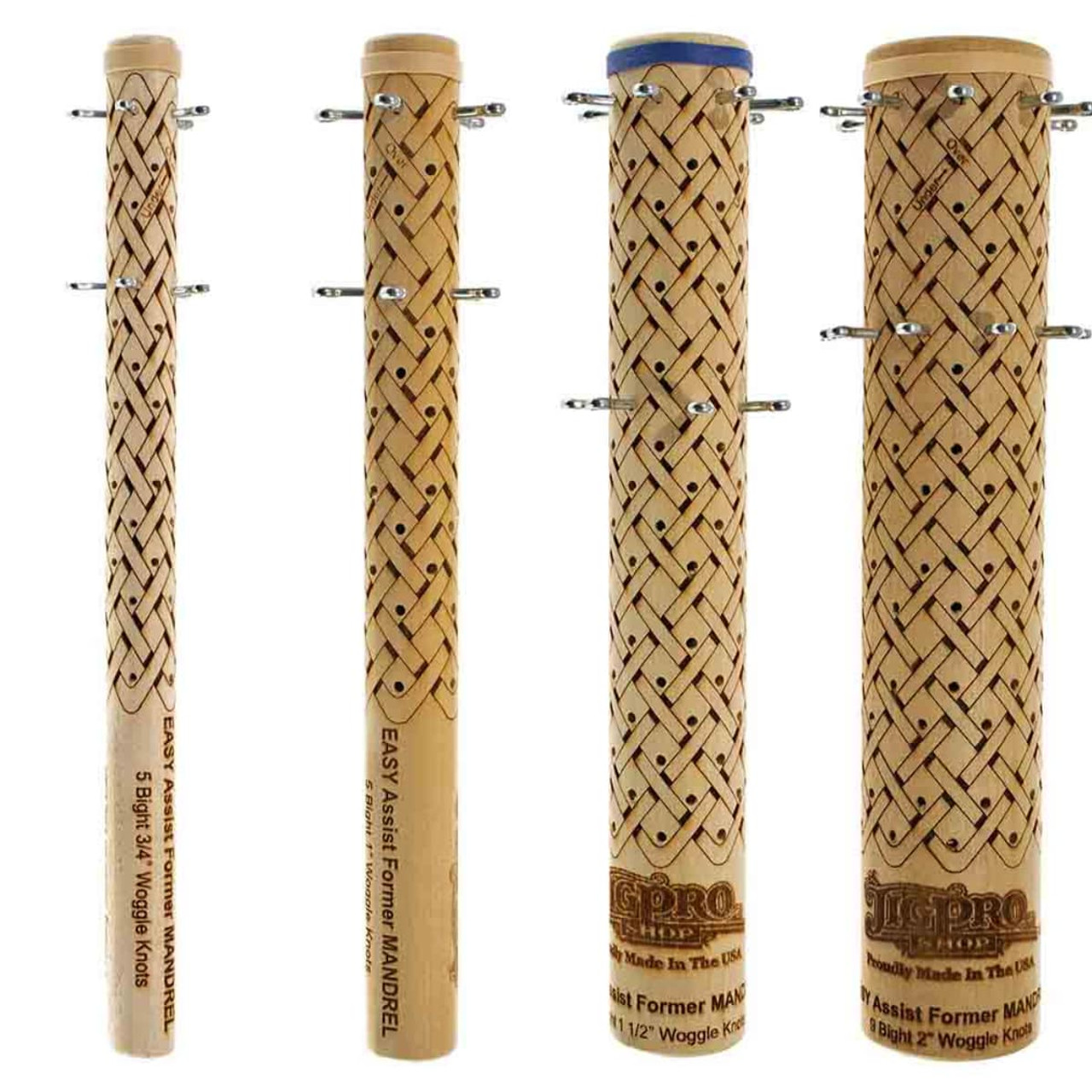

Mandrel - Wikipedia

Coil Springs: Design, Metals Used, Types, and Coil Spring Ends

Expandable Winding Mandrel, Transformer Production, Wrapping Mandrel - China Transformer Core, Mandrel

Filament Winding, Process Explained, Polymer Matrix Composites

Polymers, Free Full-Text

PDF) Heat transfer simulation and analysis of mandrel for heated-mandrel winding method of tapered shell

Filament Winding, Process Explained, Polymer Matrix Composites

Key design principles to follow for filament winding

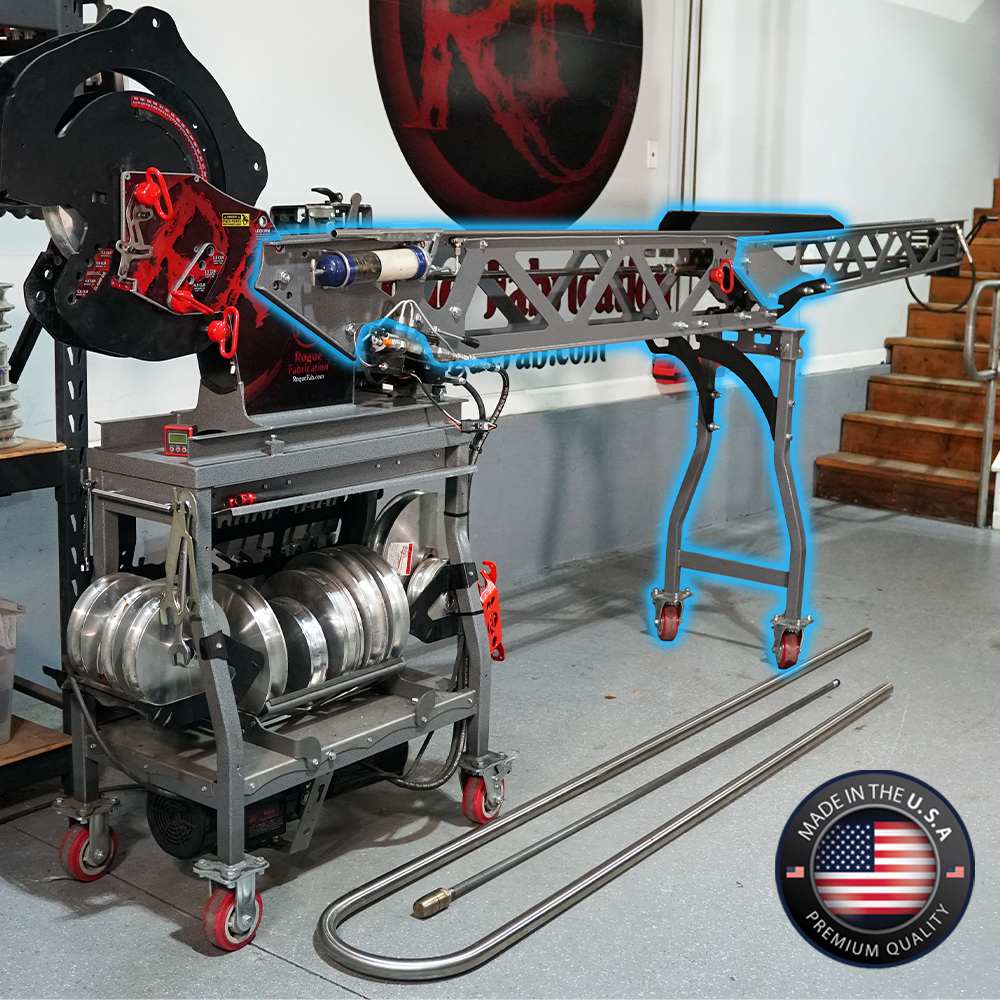

Numerical control fiber(cloth tape)winding machine_

Curves for simulated and actual temperatures. A: actual steam

Tension design of heated-mandrel winding process based on analytical algorithm - Jiazhong Xu, Yanan Miao, Ming Qiao, Shuang Li, 2014

Cfw-3000 Continuous Filament Winding Machine for GRP Pipes - China Continuous Filament Winding, Filament Winding Machine

Temperature curves and contours with flow time of 120 s.

Filament winding pattern generation for non-axisymmetric mandrels based on uniform quadrilateral elements - Ruidong Man, Seongjun Kim, Chungil Son, Yeonsu Kim, Yoongho Jung, 2021