Metallurgy - Casting, Alloying, Refining

Metallurgy - Casting, Alloying, Refining: Casting consists of pouring molten metal into a mold, where it solidifies into the shape of the mold. The process was well established in the Bronze Age (beginning c. 3000 bc), when it was used to form most of the bronze pieces now found in museums. It is particularly valuable for the economical production of complex shapes, ranging from mass-produced parts for automobiles to one-of-a-kind production of statues, jewelry, or massive machinery. Casting processes differ in how the mold is made and in how the metal is forced into the mold. For metals with a high melting temperature, stable refractory

Metallurgy, art and science of extracting metals from their ores and modifying the metals for use.

The grain refining performance test results of alloys (a) 1, (b) 2 and

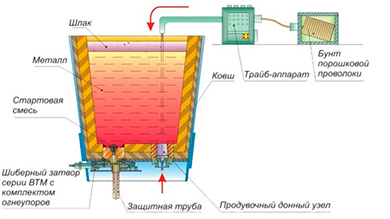

Steelmaking process - secondary refining

Grain Refinement of Alloys in Fusion-Based Additive Manufacturing Processes

Argon metal processing in the steel casting ladles. Buy Argon metal processing in the steel casting ladles. Sale with delivery in Moscow, Kazakhstan, Belarus, Ukraine, Azeibardzhan, Kyrgyzstan, Armenia, Uzbekistan, CIS countries and

Steel - Wikipedia

Metallurgy - Refining, Alloying, Smelting

Refining Scrap Gold FAQ's - The Original Gold Buyer™ KMG Gold Recycling®

2024 Casting sexuel blamiert 1080p.

Foundry and Casting Metallurgy for Dummies

Refining and Smelting Diamond Jewelry Commodity Chain

The History & Evolution of Metal & Alloy Casting

:quality(85):upscale()/2023/04/05/848/n/48337712/7bf89939642dca2ae906c1.66307470_.jpg)