Choosing Emulsion for Screen Printing Textiles – Learn How To Screen Print

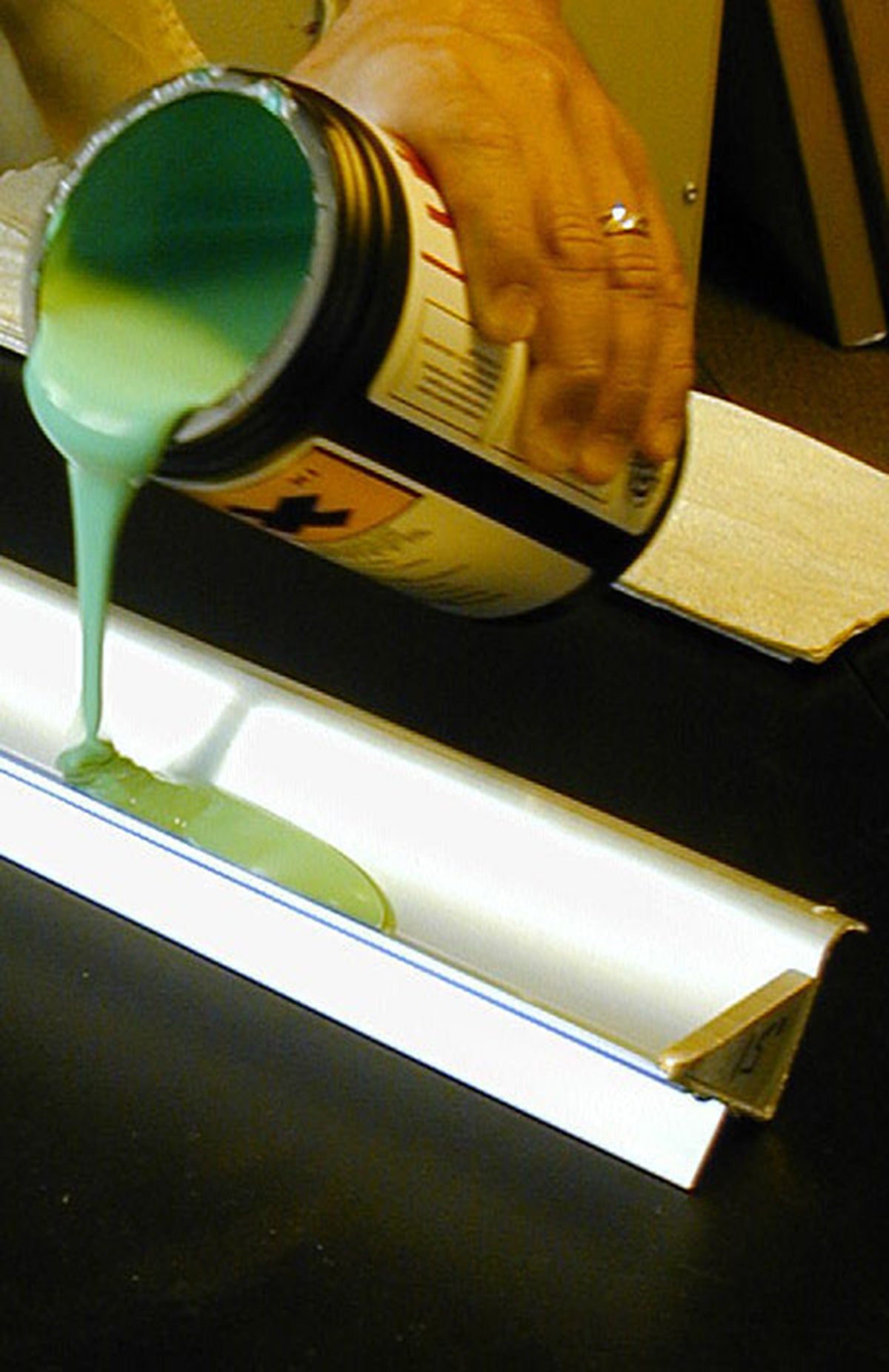

When determining the type of emulsion to use for your screen prints. There are a couple questions that can help narrow down the answer. What type of ink is the first question. Photo polymer emulsion is only for plastisol ink, and if you try using water based ink with photo polymer then your emulsion is going to break down quickly and the your stencil will be ruined.

Benefits: , Ready to use - No diazo or mixing required, Compatible with multiple ink systems - Plastisol, UV & Solvents, Produces crisp detailed

Ecotex® AP Blue Screen Printing Emulsion

Photo-emulsion Screen Printing : 7 Steps (with Pictures) - Instructables

How To Choose Emulsion for Screen Printing

Photo-emulsion Screen Printing : 7 Steps (with Pictures) - Instructables

Screen Printing Tutorial

Shipping Allow 1-3 Days Looking for emulsions is a difficult process, if you’re looking for the swiss army knife of emulsion AP-Blue is the perfect

Ecotex® AP Blue Screen Printing Emulsion (Gallon - 128 oz.) Pre - Sensitized Photo Emulsion for Silk Screens, Textiles, and Fabric - For Screen

Screen Printing Tutorial

Screen Printing Tutorial

No emulsion screen printing.

Which Emulsion is Right for Me?

EASY TO USE ALL-IN-ONE KIT: Comes with pre-stretched silk screen with Aluminum Frame, Wood Squeegee fitted with a 75 shore medium stiffness blade,

Trailblaze Professional Grade Silk Screen Printing Kit, Perfect for DIY T-Shirt Photo Emulsion Paper Fabric Printing | Screen Printing Starter Kit