Side-pressing laminated bamboo lumber production process: (a

Download scientific diagram | Side-pressing laminated bamboo lumber production process: (a) original bamboo; (b) splitting; (c) original bamboo strip; (d) peeling; (e) bamboo strip; and (f) laminated bamboo lumber. from publication: Size Effect on the Compressive Strength of Laminated Bamboo Lumber | The size effect on the axial compressive performance of laminated bamboo lumber is studied through compression tests on three groups of short columns with different heights and section sizes. The failure modes, bearing capacity, strain distribution, and deformation capacity | Bamboo, Lamins and Compressive Strength | ResearchGate, the professional network for scientists.

Side-pressing laminated bamboo lumber production process: (a) original

Summary of bamboo-based panel production processes. (a) Flattened

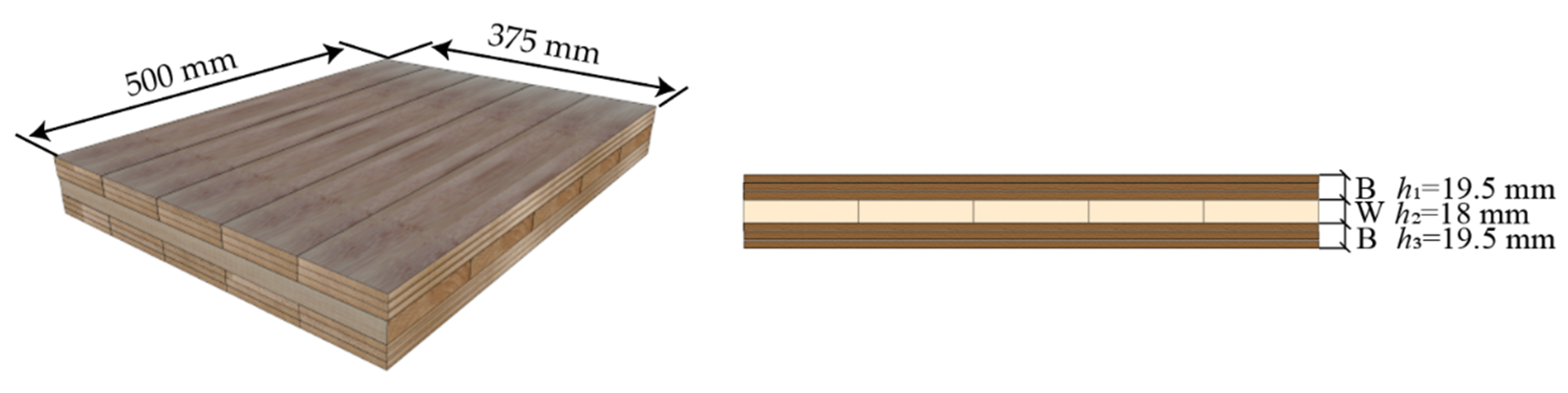

3-Ply Natural Color Vertical Cross-Laminated Bamboo Plywood for Laptop - China Bamboo Plywood, Bamboo Board

Mode 2 failure state (C50-14): (a) A side; (b) B side; (c) C side

Side-pressing laminated bamboo lumber production process: (a) original

Mechanical behavior of laminated bamboo lumber for structural application: an experimental investigation

Effect of nodes on mechanical properties and microstructure of laminated bamboo lumber units - ScienceDirect

Rodolfo Lorenzo's research works

Side-pressing laminated bamboo lumber production process: (a) original

Polymers, Free Full-Text

Forests, Free Full-Text